How to Fix Tire Rubbing on Arrma Fury (ProLine Badlands)

Introduction

You just installed those sweet new ProLine Badlands. The truck looks killer. You bring it to your buddy’s house to show it off. Then you set it down, hit the throttle and... bruppp….bruppp…bruuppp. Huh? That’s not right. You pull the motor. Check the gears. Inspect the A-arms. Nothing's binding. So what gives? Well, you have a rubbing problem. Don’t worry, this happens to all of us from time to time.

I have been really impressed by the Arrma Fury. I would dare to say… indestructible… like crazy indestructible. I have carwheeled these trucks,’ and they just keep on ticking. If they were watches, they would be a Timex.

The problem

As I praise the truck, I am hitting on one of the downsides. If you change the tire setup, you will have to trim the body. The ProLine Badlands will rub the body. This has been my experience when I combined it with the Proline SCT Beadlock wheels.

So, all good things have their limitation. The Arrma Fury is a good thing, but it has a few limitations. I emphasize a FEW.

Diagnosing the Problem

You pull the body off, you look at the truck, and the tires seem fine. No flat spots, no issues that seem to jump out at you. It sounds like a kid just put some baseball cards in your spokes.

You drive it again, and it makes the same sound. This time, you notice something. When you put the truck down, then you notice that when you load the suspension that the tires rub into the body just a little bit.

On a deeper inspection, you will notice that the tires are rubbing the body. The knobs are just clicking on the wheel well a little bit.

The other problem is that you try to resolve this, and you make the wheel wells big enough to put Bigfoot tires on them. Not the furry beast, but the monster truck. You don’t want the wheels to be that big!

This is not a big deal. You just take some time and trim a little at a time.

Let’s Do Dis Ting…. (Jersey coming out)

All you need

Lexan scissors

Patience

Make sure this is your own fury. (Friends don’t cut other friends’ Lexan without permission.)

Why the Lexan Scissors?

I guess you could use a hobby knife. In my experience, this takes a lot of cuts, and I have had hobby knives get a mind of their own. You want to cut one way, but the knife is like, “Oh no…. I want to go this way!” Now you end up with square fenders for round wheels. Or fenders that can hold Bigfoot’s tires.

I like the curved scissors. When in doubt, I get Tamiya modeling products. You can try cheaper, and there are tons of options.

The important thing is that the scissors are not going to buckle when you cut the Lexan. Honestly, these are probably made by the same company, so check your hobby store if you don’t buy Pro Tec, Team Associated, or Tamiya. I find that their tools are consistent, and I would buy them sight unseen. Otherwise, I would pick up a pair the next time you are at the Hobby Store. They are not much money, and they are nice to have in your kit.

Find the Rub

Push down on the back end of the truck, and you should see where the knobs are touching the fender. (See the pic above) I find that it is easiest to trim the wheel up to the body crease or just under it. You will start seeing where the knobs are rubbing into the body.

Just keep going round the wheel. You don’t want to hack off a ton of plastic, but just enough. Keep trimming away. Yes, this takes time. You will keep pushing down until you notice that the tires hide perfectly inside the wheels. Eventually, you will see that the knobs no longer grab the plastic. I find that it helps to keep placing the body over the wheels to get the shape of it. You will get it. Just be patient.

Now, if you did it right, you should not even notice much of anything different. The picture below is the trimmed fender.

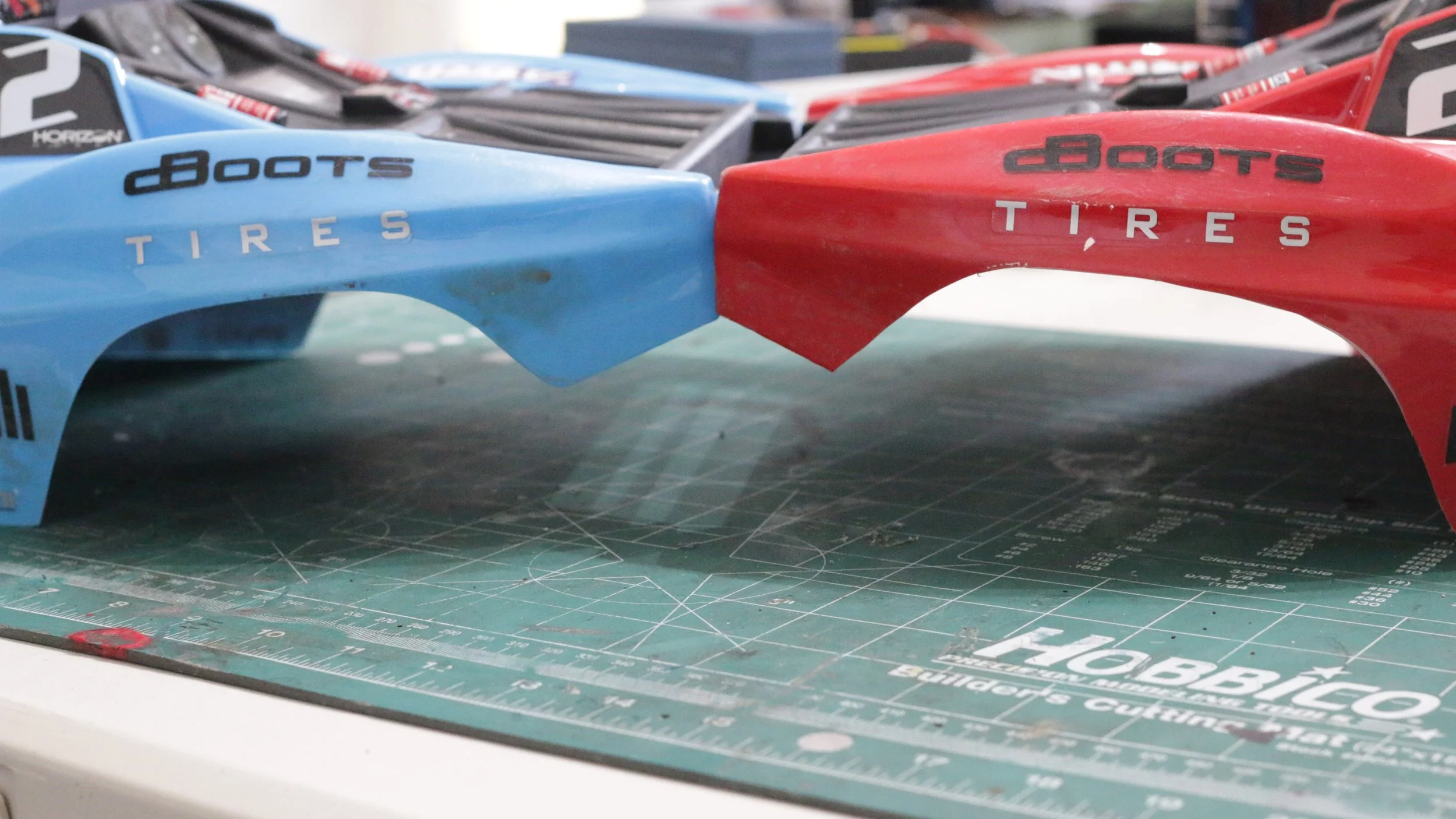

Here you can see the two bodies placed back to back. If you take your time with the trimming, the bodies will not be noticeably different. The blue one is still stock. The red body is the one that I trimmed.

Whatcha Learn?

I am always amazed at how this hobby teaches you something new. I set out to solve a problem. It was the problem of a noisy truck. I studied the problem, diagnosed the problem, and then came up with the strategy to fix the problem.

I know that so often I first try to buy something, or figure out what needs to be replaced. On this project, nothing needed to be replaced. Rather, all I had to do was take some time and observe how the wheel was interacting with the wheel well.

So I learned that it pays to slow down and diagnose the problem. Ordering parts or bolting new stuff to a truck is not always the best solution. All I really needed was some time and a $15 pair of scissors.

This is something that is a life-changing skill. It is not that every problem is solved with scissors, but many times problems can be solved by slowing down, taking another look at the problem, and proceeding with a new plan.

Conclusion

I am glad that I could figure out a solution without radically changing the look of the truck or ordering a new body. The look of this truck is really starting to grow on me. I really wish Cyber Truck would harness some of the design cues. Arrma figured out how to make the Fury look like an electric truck, but also add some curves. Tesla, are you listening? There are more tools in the toolbox than just a ruler. You can put some curves in the body. Just ask Arrma!

Now, you can get some aftermarket wheels for your Arrma and make a great truck even better!

Thank you again for reading! Remember to use social media to be social! Have you had this problem with other tires on the Fury? Comment below and share your solution!