One Traxxas Servo Fixed

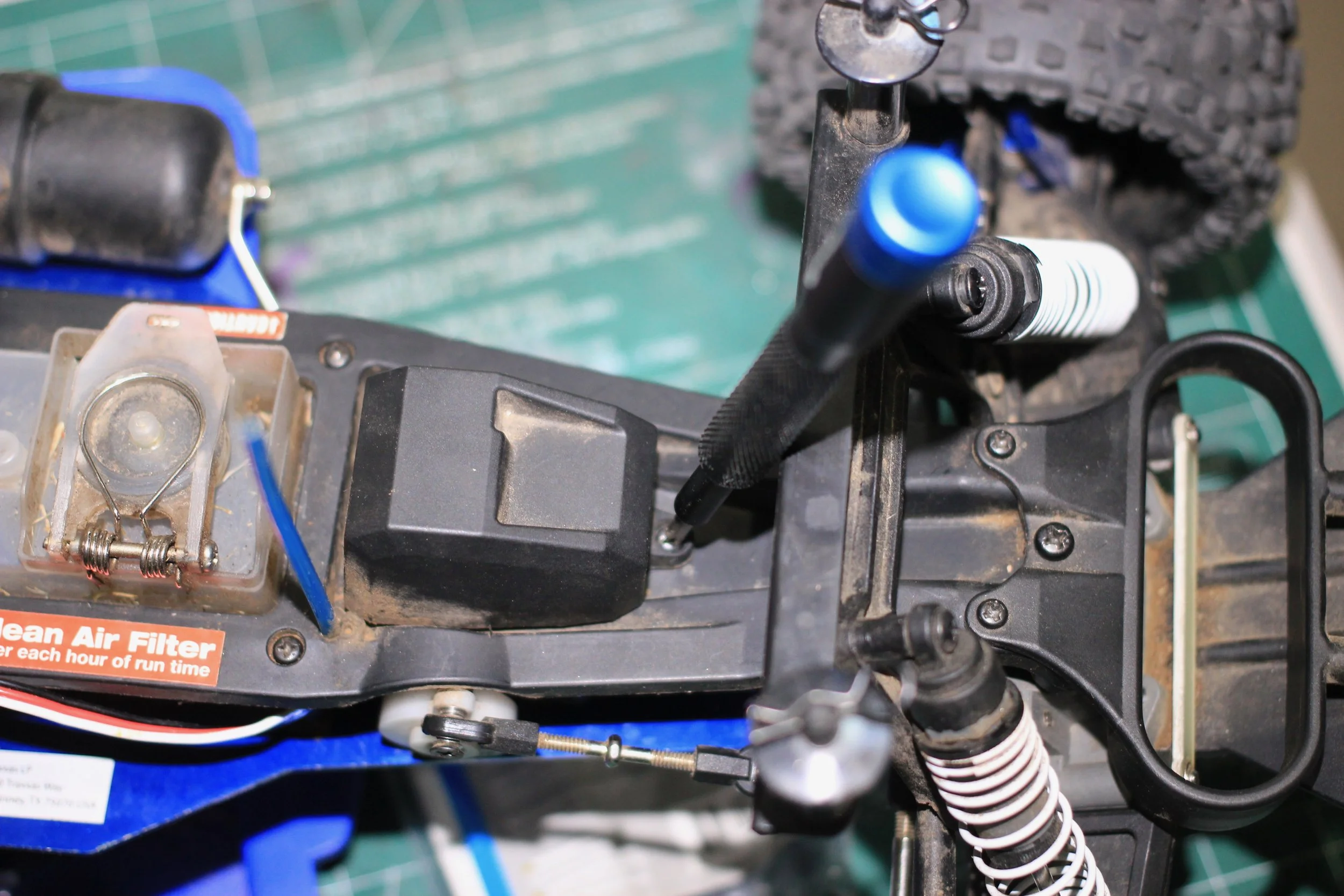

One of the failure points that people say about Traxxas is the servo. I really thought that this was just the internet being the internet. I thought it was a bunch of people dumping on a company that is successful, and they were jealous. That is, until I jumped on the bandwagon. Now, the opinion is informed rather than just some weird blogger writing about it. Wait a minute…. Well, let’s not get too deep on that one. The reality is that the throttle servo has been giving me some trouble. Batteries, adjustments, you name it…. the servo just was not consistent.

I called A Main hobbies and got their recommendation. Now, I know I pump A Main Hobbies and I should let people know that A Main does not support me. In fact, they do not give me free stuff or swag. I earn the money, I hand the money over to them, and I get cool stuff in the mail. Personally, I would love to skip to the last part on this list and not have to deal with the first two parts.

So, why A Main? I love their customer service, and I also trust their recommendations. They recommended that I replace the Traxxas servo with the Eco Power Servo WP120T. It turns out that this is an in-house servo. I had no idea that A Main does their own servos, but apparently, they do. This recommendation left a bit of a sour taste in my mouth as I normally prefer Hitec servos.

I normally select HiTec, but the cheapest HiTec that would work in the Slash is probably the Hitec D950TW. It is 129.99, and it only claims to be splash-proof. My goal is to see if I can build a really good, reliable nitro truck on a budget. So, I decided to branch out and go with the A Main brand. I think I finally stopped pacing the room, but sleeping in a fetal position is concerning my wife. Alright, so branching out is not that dramatic for me…. but close. This servo is not as cheap as servos go, but it is less money than the Hitec I was considering. So, we will call this a semi-budget build.

Let’s Get to it!

The package is pretty nice, and a nice package generally communicates to me that they put thought into the brand a bit. The servo is made in China, not the US of A, but Hitecs are made in Vietnam (cheaper servos, I believe, their analogue and roughly below a 100-dollar price point). The higher-end Hitecs (D Series, brushless, titanium gears, industrial servos) are made in South Korea. They are headquartered in South Korea, so that would make sense that their higher-end servos are made where they can keep an eye on quality control.

The very first thing that I noticed about the Eco servo compared to the Traxxas is the quality of the wires. The Traxxas servo has a very small gauge wire. Traxxas runs their 2055 servos in the Slash nitro.

The pic does not do it justice, but the wire thickness and flexibility is immediately apparent.

I discovered another problem when I pulled the servo screws out that mounted the servo; I found out that the plastic mounts on the servo were broken. So, now I see why the throttle seemed to respond well, and then other times it did not seem to open all the way. I think the servo was sliding back and forth on the mount.

I really do not know how that happened. I have never seen a servo crack like this. All I can think is the truck was driven a lot with the body off and rolled many, many, many, and many more times. I bought it used, so the previous owner, and who knows what happened.

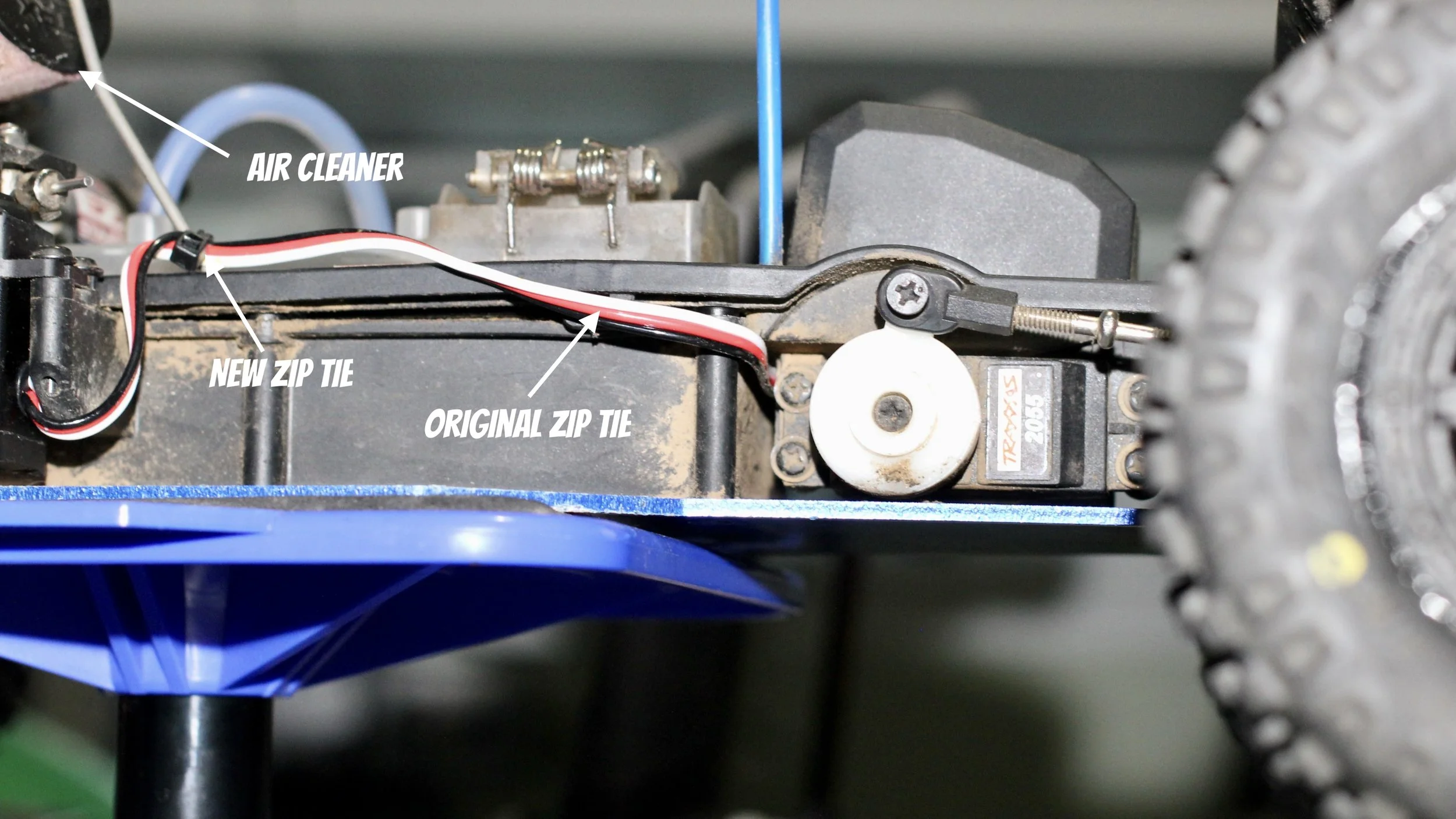

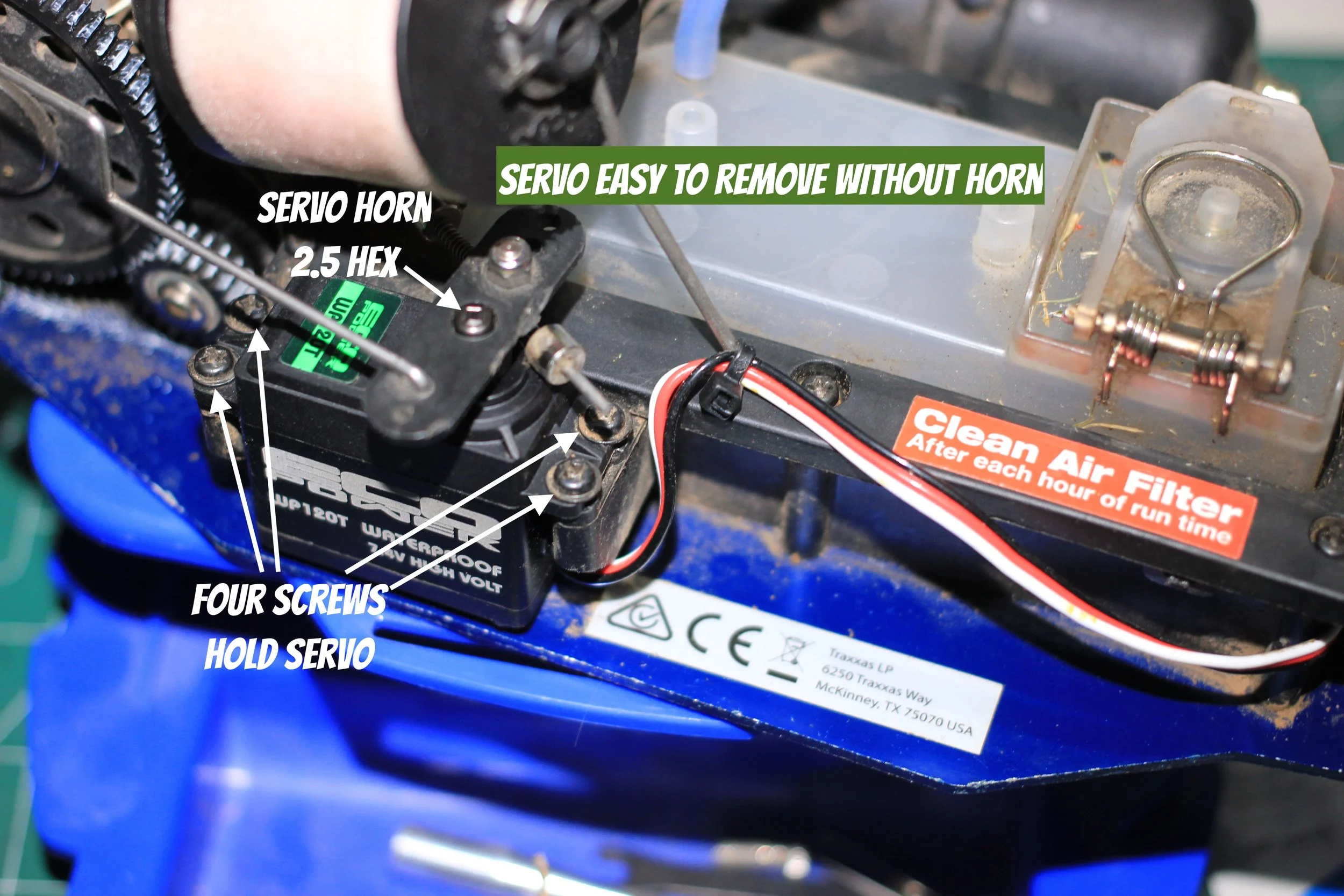

First, I took off the cover for the transmitter, removed the servo wire from the receiver, cut the zip tie with Lexan scissors, and unscrewed the four screws that hold the servo.

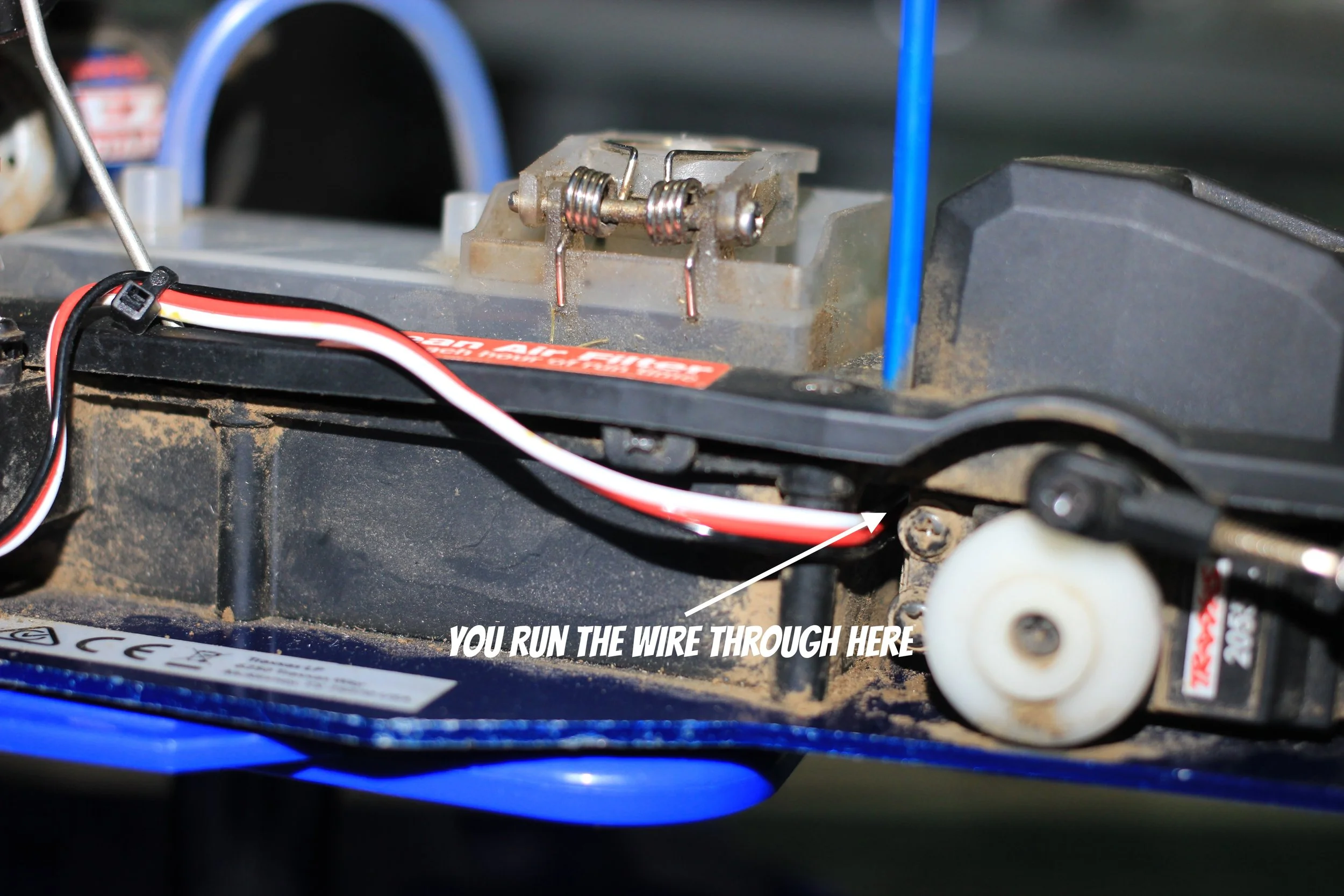

Carefully cut the zip tie, and then pull the wire that says throttle. You can work the wire out, and then pull it through the hole that is on the plastic mount.

Second, when you remove the wire, it runs behind the steering servo and under the plastic housing. You can wiggle it out easily enough, but putting the new wire in this same place is like a game of Operation. Thankfully, there is no annoying buzzer... However, one’s patience will be tried when running the wire. I used a pair of PC tweezers (yes, affiliate link) that allowed me to grab the servo plug when I saw it, and then I could pull it through the slot.

I cut the factory zip tie, but could not completely remove the zip tie. I gave up trying to remove the factory zip tie, mostly because I lost patience. I will see if it eventually falls out after running the car a few times.

Then I took out the new servo from the package. They have really nice packaging. I got the servo out and lined it up next to the old one. Looks like a perfect fit, which is what we would expect. The servo comes with a series of bushings, screws, and horns. So, good job on Eco Power or A Main. I chose to reuse the horn that came with the Traxxas servo, as I normally do. This one worked just perfectly, but sometimes you do have to swap them out and do all the additional adjusting. Thankfully, that is not the case here. I had to reverse the servo on my transmitter, but that is not a big deal. Overall, it worked well and even better. You can see that while the Eco Power fits like a glove, it definitely has more beef, and the Traxxas servo seems to have more bun. Personally, I don’t like the bun, so I’m going with the Eco Power servo. I am referring to the Wendy’s commercials in the 80s…. Click the YouTube link… you’ll see why Gen Xers have some issues.

You can see that the Eco power is a bit beefier. Yes, it fits in the same spot, but at least the housing gives some assurance that the internals are a bit stronger as the Traxxas servo is dwarfed.

The new servo seems faster. I am not sure how that is going to impact the throttle response at this point, but it seems faster. I hope it is faster; the butt dyno never lies, right? Well, sometimes it can be confirmation bias, but I say: faster! The tools that you will need are simply a screwdriver and a 2.5 hex (affiliate link…. I get small clams in commissions if you see the link). That should be it, and you are ready to dive into the project. Basically, you unscrew, unplug, remove the wire, rerun the wire, plug, and then screw the servo onto the servo mount.

I want to rebind my transmitter to the receiver to make sure that all my fail-safes are set. So, I put the transmitter in bind mode. I will hold the brakes on when I hold the receiver button to bind the receiver to the controller. What way when the transmitter starts talking to the receiver, it knows to hit the brakes if they stop talking. I really hate passive-aggressive RC cars.... sorry, I forgot to warn you about the dad joke. Now I replace the receiver cover.... looks good... I like it ah LOOOOOOT!

The main thing left for right now is to play Elvis and leave the building. Let’s take it outside and see if we can drive it without breaking it.

Conclusion

Well, I did get the servo to work. It does seem a little more responsive, but that is probably mostly because I just spent time replacing the old servo and writing about it. It is definitely an upgrade from the Traxxas servo. I still like the truck, but the thought of building a budget Nitro Short Course Truck is fading. If you are on a budget, then I suggest going to Aarma Fury. However, if you want the pure sound of Nitro in a short-course truck, then Traxxas has the market. So, I will keep this one and enjoy it for the time being. We ran a few tanks of gas through the truck, and it really performed well! I would recommend this servo, and if something changes, I will let you know. Until next time, get out, do something fun, look for opportunities to be generous, and may the Lord’s blessing and peace be upon you.